ROBOCAM software: The robot CAM system from Tezmaksan

In the ever-evolving landscape of industrial automation, ROBOCAM stands at the forefront of CNC robot programming, representing the culmination of our relentless journey towards simplifying and enhancing the robotic engineer's role in the machine tool automation process.

It all began with the introduction of our CubeBOX robotic automation system, and from there, we set our sights on creating a solution that empowers operators, regardless of their industrial robotics programming knowledge and experience.

One of the major breakthroughs achieved with ROBOCAM is the seamless integration of solid models of workpieces into the system. This software negates the need for intricate robot programming and extensive CAM knowledge. By converting 2D CAD drawings into CAM instructions, RoboCAM simplifies the entire process, making it accessible even to operators without specialised training. This reinforces Tezmaksan's commitment to Industry 4.0 principles, offering comprehensive solutions that encompass turnkey projects, integration, installation and ongoing support services.

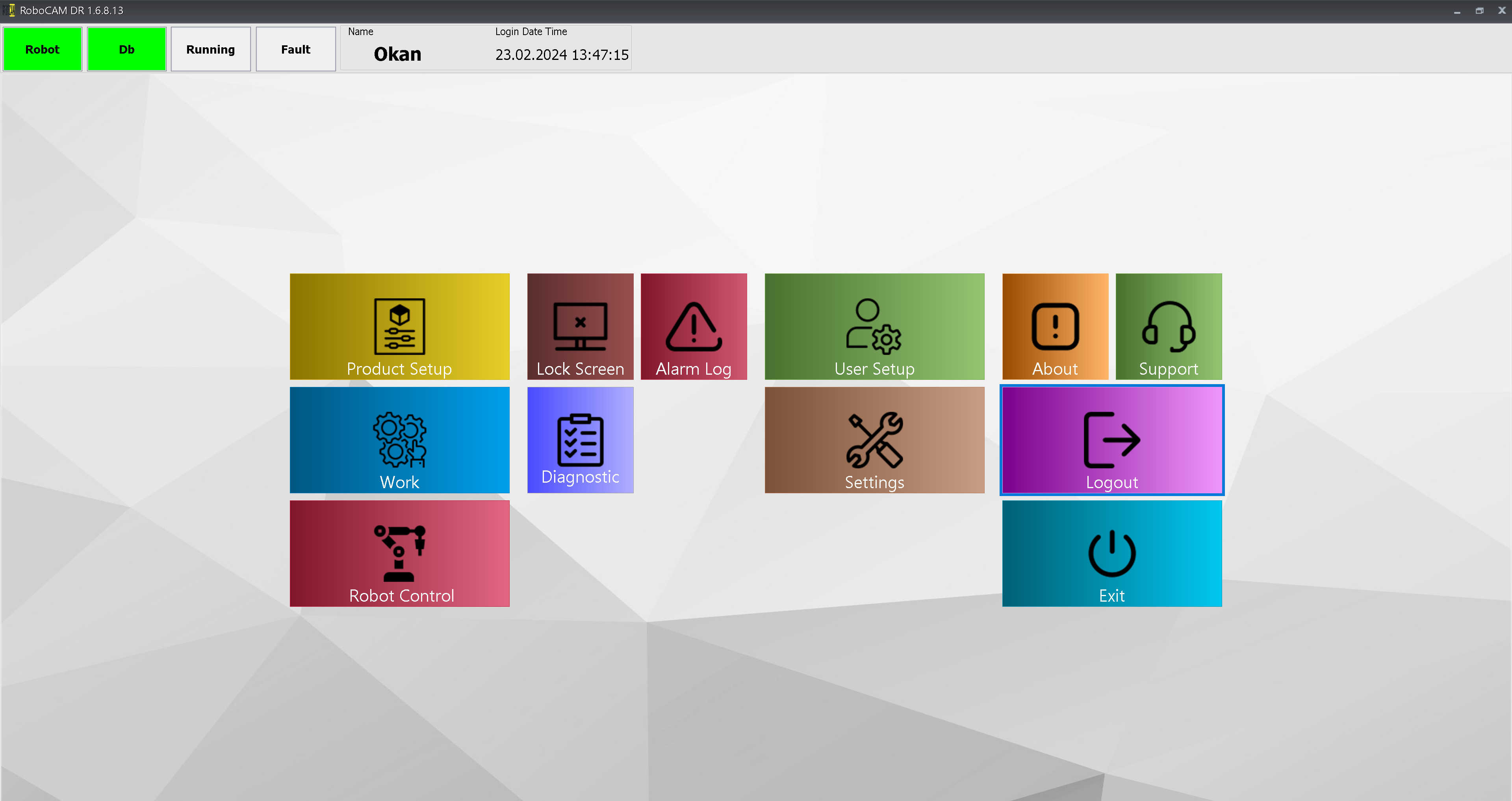

Thanks to our user-friendly ROBOCAM software, developed in-house by our dedicated software team, the complexities of robotics programming are now a thing of the past. This leap in technology not only simplifies the operator's tasks but also significantly reduces the time spent on robot reference definition processes.

In a matter of minutes, operators can implement new parts into the system. Tool changes have traditionally required extensive robot programming knowledge and prolonged changeover times.

The ROBOCAM process is remarkably straightforward: provide the dimensions of the part, specify the attached tools on the robot, input the CAD drawing of the inlay, and define the workflow for the robot's intended stations.

Our innovative software effortlessly extracts position data from the inlay drawing and seamlessly transmits it to the robot.

All that remains is a simple press of the "start" button, and the CubeBOX robot springs to life. The operator is in full control, even without any prior robot programming expertise. It's a testament to the power of technology in simplifying and democratising robotics applications.

ROBOCAM CNC programming software compatible with all robotic systems

ROBOCAM was initially designed to complement our CubeBOX robot automation systems but has expanded its horizons. It's no longer confined to a single robotic platform — instead, it serves as a versatile CNC software solution that can be integrated with all robotic CNC machines. This adaptability makes ROBOCAM an invaluable tool across the automation industry.

What truly sets ROBOCAM apart is its ability to bridge the gap between product drawings and the language robots understand. The operator's role primarily involves loading and unloading the magazine, making the entire process more accessible and efficient than ever before

How to Use ROBOCAM?

Embracing ROBOCAM is a straightforward endeavour, requiring just five quick steps:

- Input part dimensions: Begin by providing the dimensions of the part you intend to process. ROBOCAM streamlines this step, eliminating the need for intricate measurements.

- Specify robot tooling: Define the attached tools on the robot. This step is intuitive and user-friendly, making it accessible to operators with varying levels of experience.

- Upload CAD inlay drawing: Incorporate the CAD drawing of the inlay. ROBOCAM's intelligent software ensures a seamless integration of this data into the workflow.

- Configure workflow: Detail the workflow by specifying the stations the robot needs to access. This step is a breeze, thanks to ROBOCAM's automation capabilities.

- Press "start": With all parameters in place, all that remains is to begin the workflow and ROBOCAM sets the robot in motion.

Whether you're a seasoned professional or new to automation, ROBOCAM's user-friendly approach ensures efficiency and precision. With its universal compatibility and exceptional capabilities, it is poised to revolutionise the future of industrial automation, one simple step at a time.

Check out our full range of Digital solutions in manufacturing.

Contact us today to embark on your automation journey and witness the tremendous benefits of CubeBOX and ROBOCAM

NEW VERSION : ROBOCAM PLUS

“ROBOCAM+ is a software with many technical advantages.”

- Reading and working with DXF file

- Creating user-specific matrix and saving DXF file

- Creating a programmatic workflow that allows creating all kinds of transportation scenarios

- Floor and part tracking thanks to object-oriented structure

- Collision-error protection due to part tracking

- Duration, efficiency calculation and reporting

- Station working structure where each point of the part is defined

- Multipart operation allowing multiple parts to be stacked in the tray slot or stations

- Currently fully compatible with Fanuc and Kuka robots. (Our work continues for other brands)

- Programming logic similar to commands within the robot

- Option to work by calling programs within the robot

- Recording and reuse of robot movement positions

- UFrame calculation from 3 points

- Real-time display of cells created with RoboCell with 3D modeling

- Ability to choose theme (Blue, Dark and Light)

- Language support

- User account and authorization

- Automatic update and license check

- Easy setup